Four Benefits of Sintered Mesh Filter Products

SMFB-1 5-layer sintered mesh filter cartridge

Sintered wire mesh filter integrates the pros of woven wire mesh which enjoys micron-rated aperture for fine filtration and diffusion-bonded mesh laminates which provides mechanical strength and stability. Generally speaking, fine woven wire mesh filter is placed in multilayer sintered laminates. The laminates protect the fine mesh from mechanical damage from the environment pressure. 5-layer sintered laminates is popular for it's much stronger than 3-layer. See the features of different layer below.

Owing to its stability, mechanical strength and durability, sintered wire mesh can be manufactured into various sintered filter elements like cylinder, cartridge, candles and discs. We still supply bespoke sintered mesh filter for your special requirements.

Product specification:

- Item: sintered mesh filter.

- Material: stainless steel 304L & 316L (aluminum on order).

- Layer: single, 2 to 3, 5-layer & 6-layer or custom.

- Sheet sizes: 18" × 48", 24" × 48".

Applications:

- Oil & gas production.

- Pharmaceuticals.

- Chemical industry.

- Food.

- Aerospace.

- Polymer filtration.

- Refining.

- Energy & Nuclear.

Advantages of sintered mesh over typical woven mesh:

- Diffusion bonded or sintered multi-layer woven wire mesh has better mechanical properties.

- Sintered mesh has stable pore size.

- Easy to fabricated into cylinders, candles & baskets for deep filtration.

- Cleanable, reusable and durable.

Properties for sintered wire mesh with different layers

-

Single layer sintered mesh:

SMFB-2 Single layer sintered mesh filter

Sintered woven wire mesh filter is closely bonded together by diffusion leading to permanent geometry, pore size and filter rating.

Features: one-layer stainless steel woven wire mesh is an alternative for low-cost mesh filter and doesn't require sealing methods according to its construction. Common shapes are round disk, ring and simple cylinder. -

2-3 Layers Sintered mesh

SMFB-3 3-layer light-duty sintered mesh construction

Sintered dutch woven wire mesh has good mechanical strength and medium aperture. The filtration layer with desired aperture is sandwiched between outer & inner protection layers.

Features: ideal for manufacturing pleated cylinder filter or candle filter and sintered discs. -

5-layer sintered wire mesh

SMFB-4 5-layer sintered mesh construction

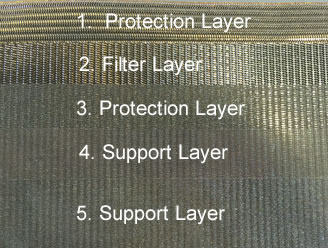

A single layer of fine woven wire mesh which decides the filtration is placed between two protective layers of coarser woven wire mesh, and then these three-layer wire meshes will be sintered together with two support-layers to improve the stability.

Features: 5-layer sintered wire mesh laminates has extensive fields in chemical processing, food & beverage, pharmaceuticals and transportation. It is used in liquid & gas filtration, fluidized beds and others. -

6-layer sintered wire mesh

SMFB-5 Perforated sintered mesh

6-layer sintered wire mesh laminates has an additional drainage player compared with 5-layer mesh.

Features: improves the quantity of the filter capacity.

Inquiry for Our Product

Boegger Industech Limited

E-mail:

sales@metalfilter.org

When you contact us, please provide your detail requirements. That will help us give you a valid quotation.